Work Process

Production Process

Production Schedule Planning

Production Schedule meeting

PP Sample Meeting

First Production Meeting

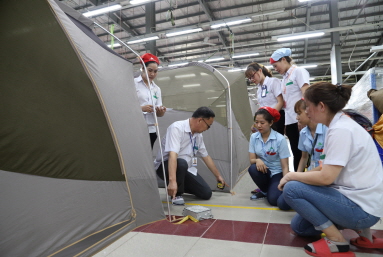

QC worker training for Defect Identification

The quality inspection team, who inspects the product's function and appearance, is regularly trained on the types of defects and items recognized by consumers as defective.

Preparation of parts for sewing

cutting, partial work, computerized sewing machine, etc.

Fabric Relaxing

Fabric binding

Fabric Spreading

Fabric cutting

Production sewing Process

Seam taping

Computer pattern sewing

Eyelet installing

In-line Inspection

Production Process

End Line QC Inspection

Folding process

Packing process

Finished Goods Warehouse

QA Inspection

Prior to product shipment, we strive to ship defect-free products by conducting product function and appearance inspections from the consumer's point of view.

Climate controlled Warehouse

Produced products are stored in a constant temperature warehouse at 26°C until packaging.